Subscribe to our newsletter and save €5 - register here!

FAIR PRODUCTION

Production under the flag of the fair wear foundation

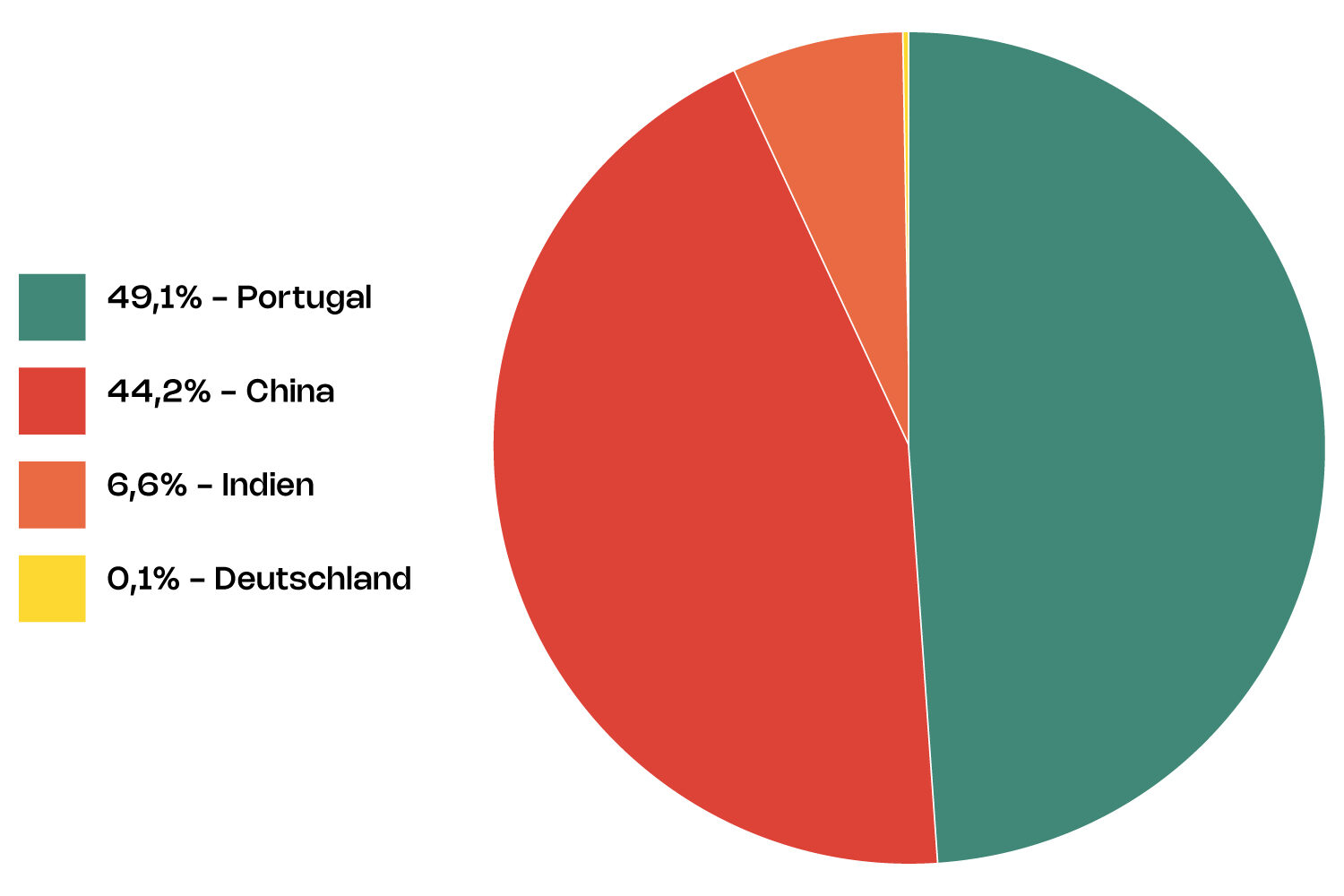

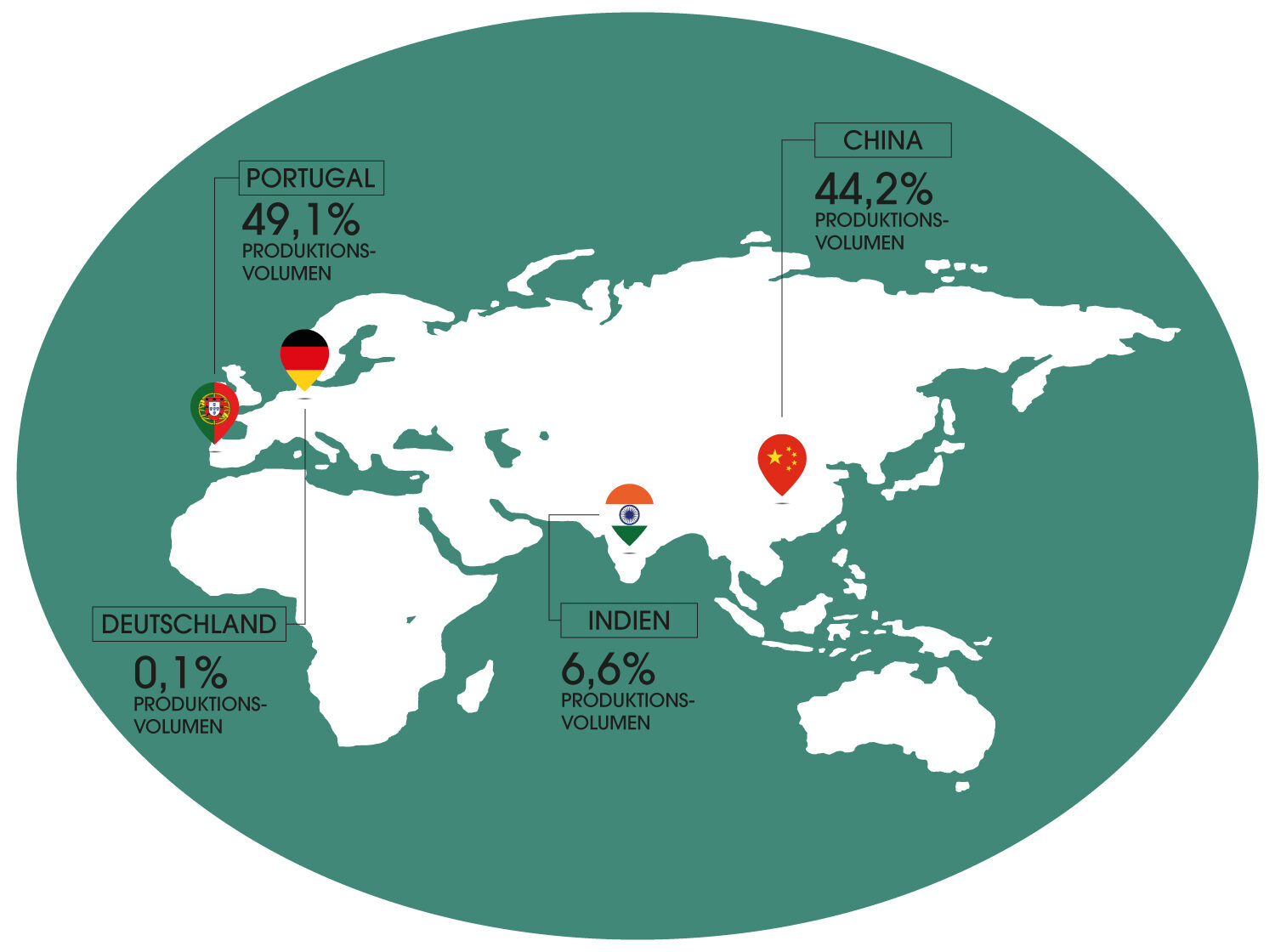

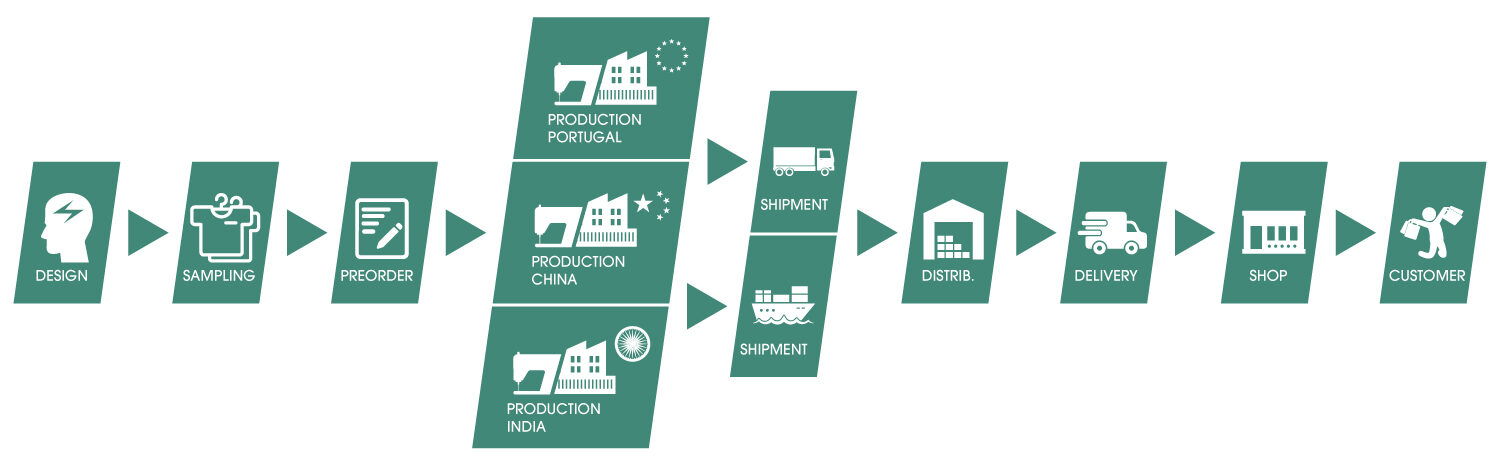

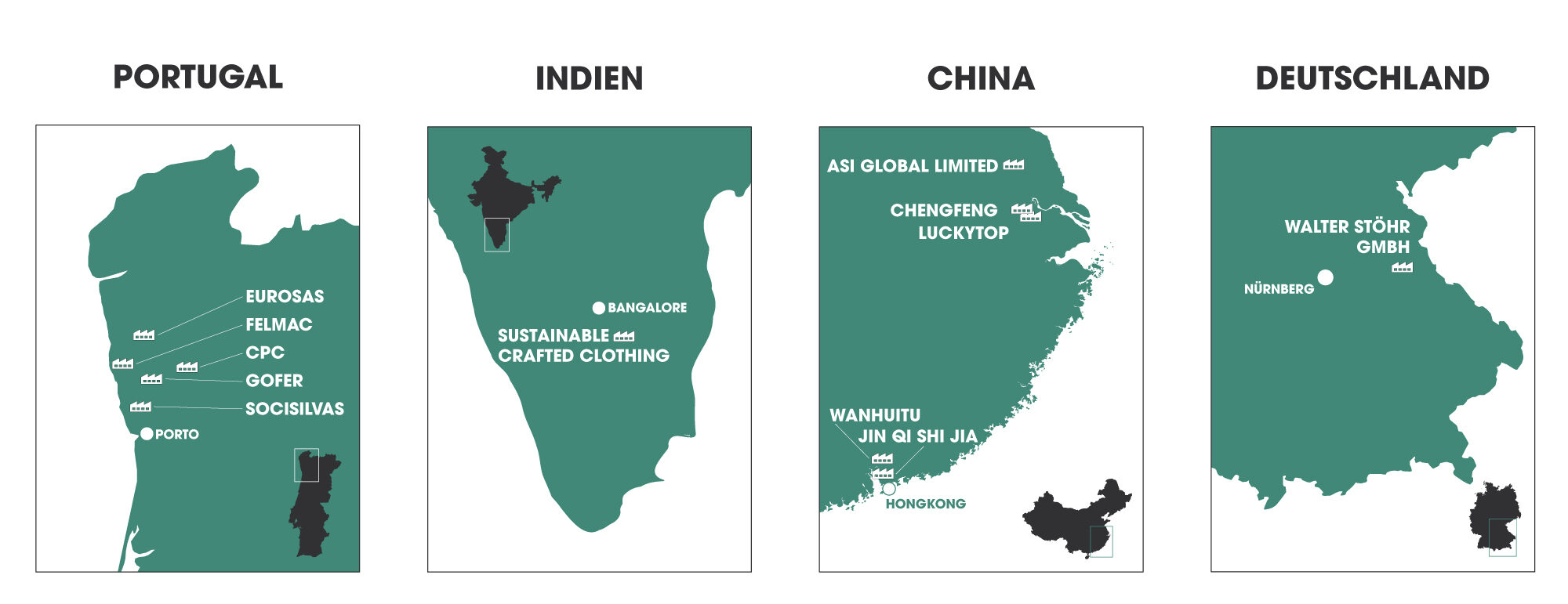

We bring out a main collection twice a year: Spring/Summer and Fall/Winter. All IRIEDAILY styles are manufactured in our production facilities in Portugal and China - since 2023 also in India and on a small scale in Germany.

What is particularly important to us: fair and safe working conditions in all factories. That is why we have been a member of the Fair Wear Foundation since 2016 and are actively committed to a transparent and socially just supply chain.

Since IRIEDAILY was founded, we have been producing in Portugal - exclusively for the first ten years. Today, a large proportion of our goods still come from there: around 49.1 % of our production volume - mainly T-shirts, sweatshirts and socks - is still made in Portugal.

Compared to previous years, our production share in China has decreased slightly and currently stands at around 44.2 %. We mainly produce jackets, shirts, shorts, pants, knitwear, caps, hats and accessories here.

In 2023, we have opened a new chapter: India is not only a new supplier, but also a new production country in our supply chain. Around 6.6 % of our products are currently manufactured there.

And even if the proportion is still small at 0.1 %, we have been offering caps "Made in Germany" for the first time since 2024.

Long-standing partnerships with our suppliers are a key component of our success. We have been working with the most important of them for over ten years - and with many of them for more than five years.

Production pressure can be particularly high in smaller factories. That's why we work with our partners to find individual solutions to reduce the workload on site. These include, for example, submitting orders early or accepting weekly partial deliveries instead of rigid deadlines.

PRODUCTION IN PORTUGAL

Our textile production began in Portugal - and we now have a partnership of over 20 years with our most important local producers. The supplier structure there is characterized by small, family-run businesses. We currently work with five of these long-standing producers who have been in business for 20 to 30 years and specialize in smaller order volumes.

Most of the workforce comes from the local area. Portuguese health and safety laws apply in all companies, and the statutory minimum wage is paid as a matter of course - 14 times a year, as is customary in Portugal.

For over 25 years, we have also been supported by a textile agency that represents our interests locally. As our requirements under the Fair Wear Foundation have steadily increased, one of the agency's employees is now specifically responsible for implementing and monitoring all FWF processes.

FACTORY VISITS 2021

Our CSR team regularly visits our production sites to check the working conditions on site and intervene in the event of problems. Together with the Fair Wear Foundation, we campaign for better working conditions and wages for workers in the textile industry. These factory visits were accompanied by a camera in summer 2021, allowing us to provide even more transparent insights into our production in Portugal.

PRODUCTION IN CHINA

Over ten years ago, we relocated part of our production to China - a big step that enabled us to grow, but also brought with it a lot of responsibility.

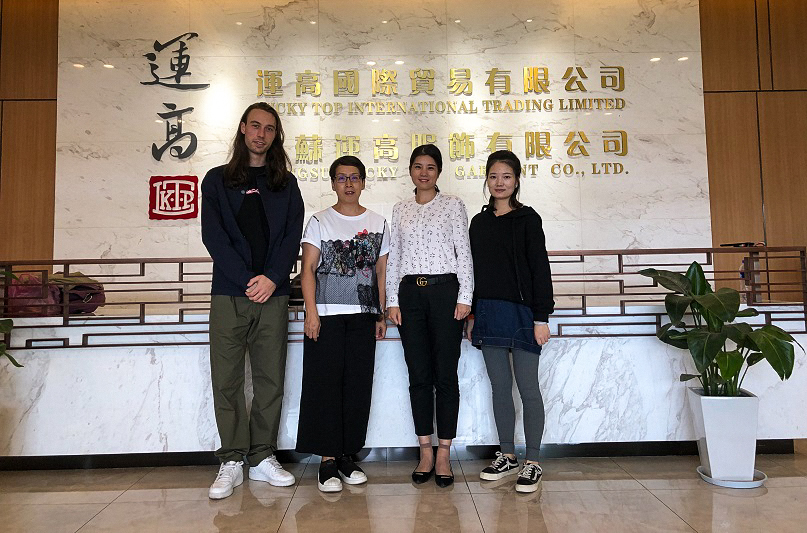

China remains a challenging country in terms of many political issues. At the same time, we are observing rapidly advancing developments there - including with regard to social standards, environmental requirements and legal regulations. We believe in our local producers and rely on long-term, trusting partnerships. We are currently working with five Chinese production companies.

Change does not happen on its own - that is why it is a matter of course for us to actively contribute to improving working conditions. In order to closely monitor the processes on site, we work together with agents and send independent auditors and trainers directly to the factories.

A first milestone: we are now able to offer a new production line for 50 %s in China. living wage - in other words, significantly more than the statutory minimum wage. This was made possible by our long-standing and close partnership with our producer LuckyTop. The remaining 50 % employees also receive more than the minimum wage. Living wages are not a nice-to-have for us, but a Must - because this is the only way to bring about long-term change in the textile industry. And we continue to work on this every day.

PRODUCTION IN INDIA

In 2023, we took an important step: we not only added a new supplier to our supply chain, but also a new production country in India. This decision was not made out of necessity, but quite deliberately - with the aim of making our supply chain more resilient and diverse in the long term.

Following the successful completion of our new onboarding process in mid-2023, we are proud to announce that With Dibella we have a reliable and strong partner at our side. The production volume in India was around 2 % in the first year and has since risen to 6.6%.

India undoubtedly presents complex challenges in terms of human rights and working conditions. This makes it all the more important to work with a partner we can trust. In Dibella, we have found exactly that partner - a company that shares our values and actively supports us in doing business in a fairer and more sustainable way. Despite the country-specific risks, we see this collaboration not only as sensible, but also as a real gain for our supply chain. A particular plus point: for the first time, this partnership gives us the opportunity to fully trace the entire supply chain - from the raw material to the finished product.